16" Telescope project

Technical details

1.- The project

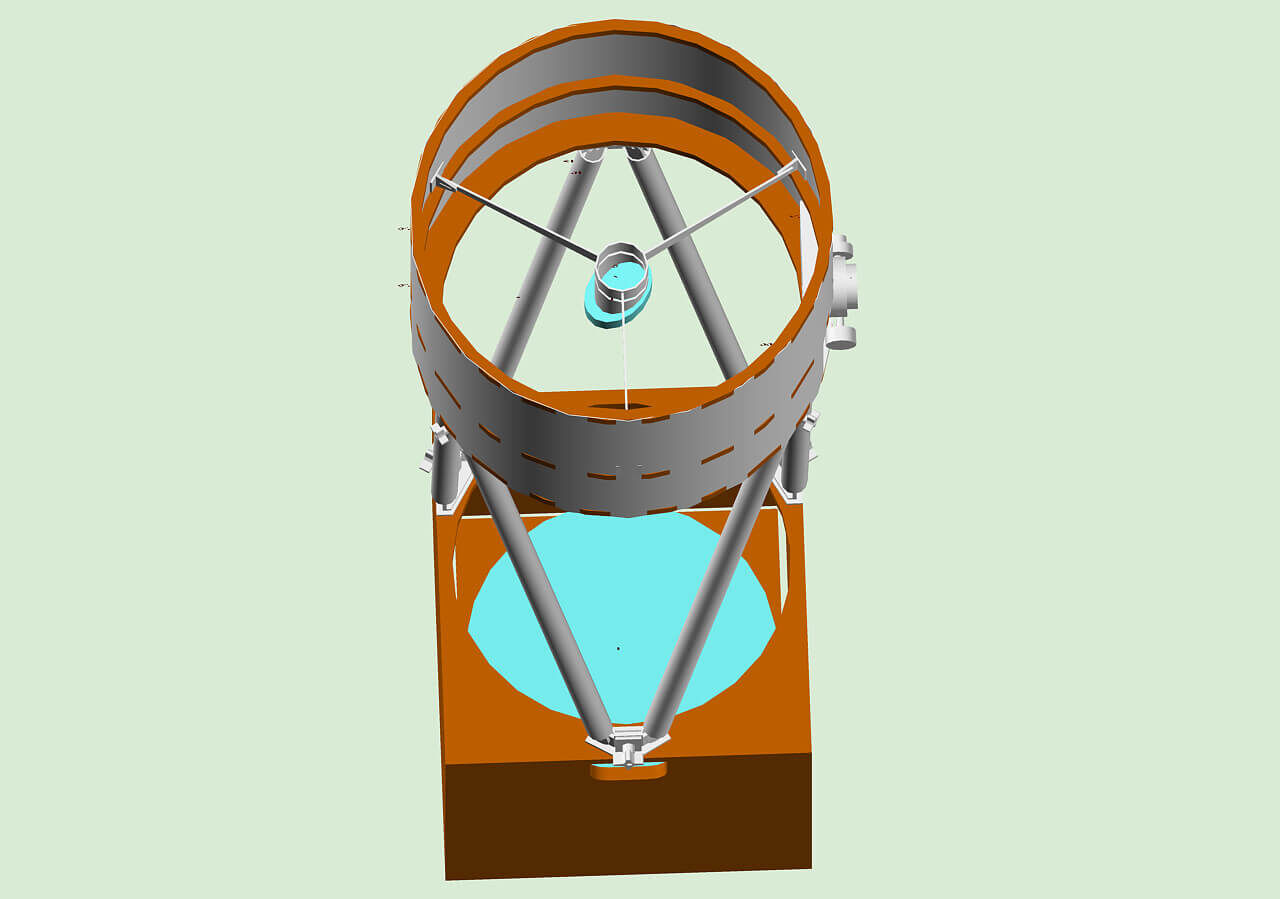

By 2016 we started the design of a huge and innovative dobsonian 16" telescope. Its construction started in January 2018. The new telescope should improve our three 16" Lightbridge MEADE existing telescopes at astroGC. The main improved features are:

- Rigidity of the telescope structure.

- Precision of optical alignment.

- Resistance of the rocker box to humidity.

- Softness and precision pointing the telescope.

- Basic astrophotography ability.

- Optical quality.

- Moon light protection.

- No flares images.

All pieces will be built locally except the mirrors, the focuser and the red dot finder.

Some of the designs and pictures shown on this section are copyright protected, please ask if you need to reproduce.

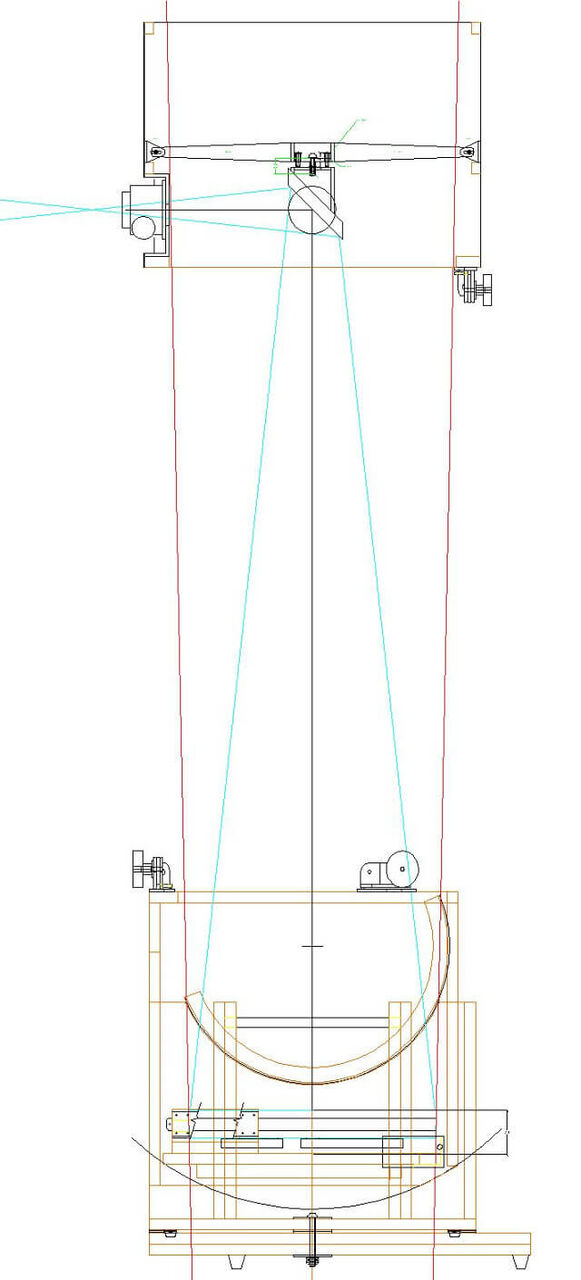

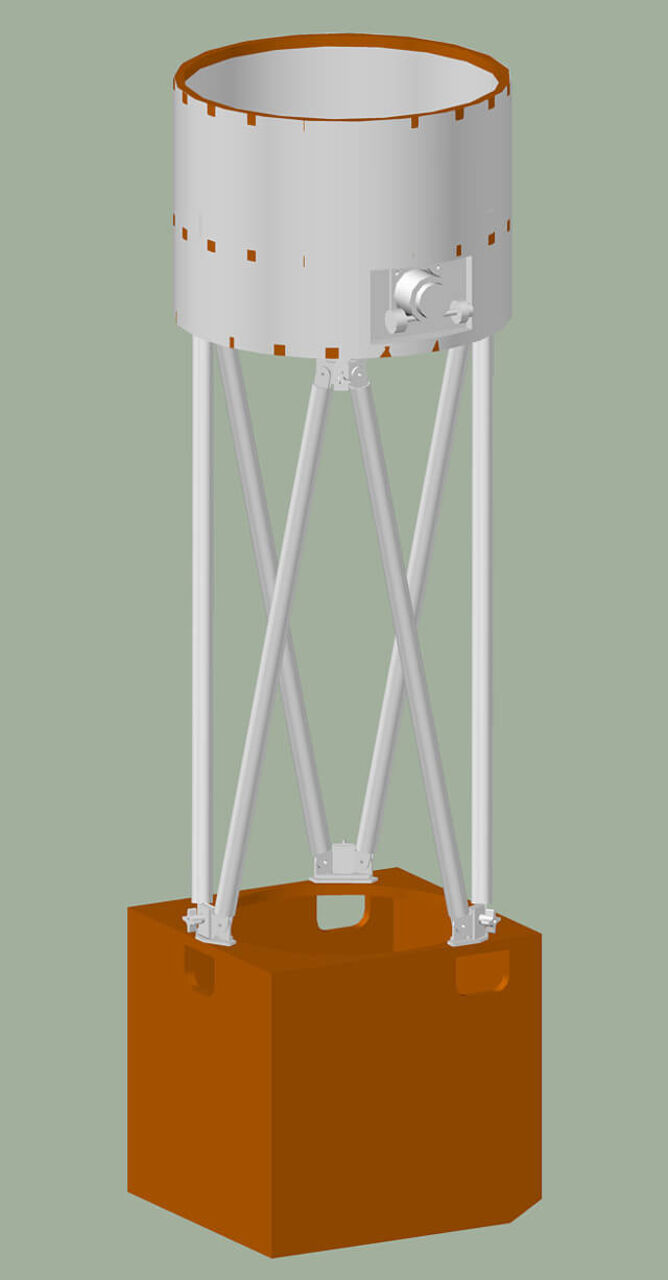

2.- Rigidity of the telescope structure.

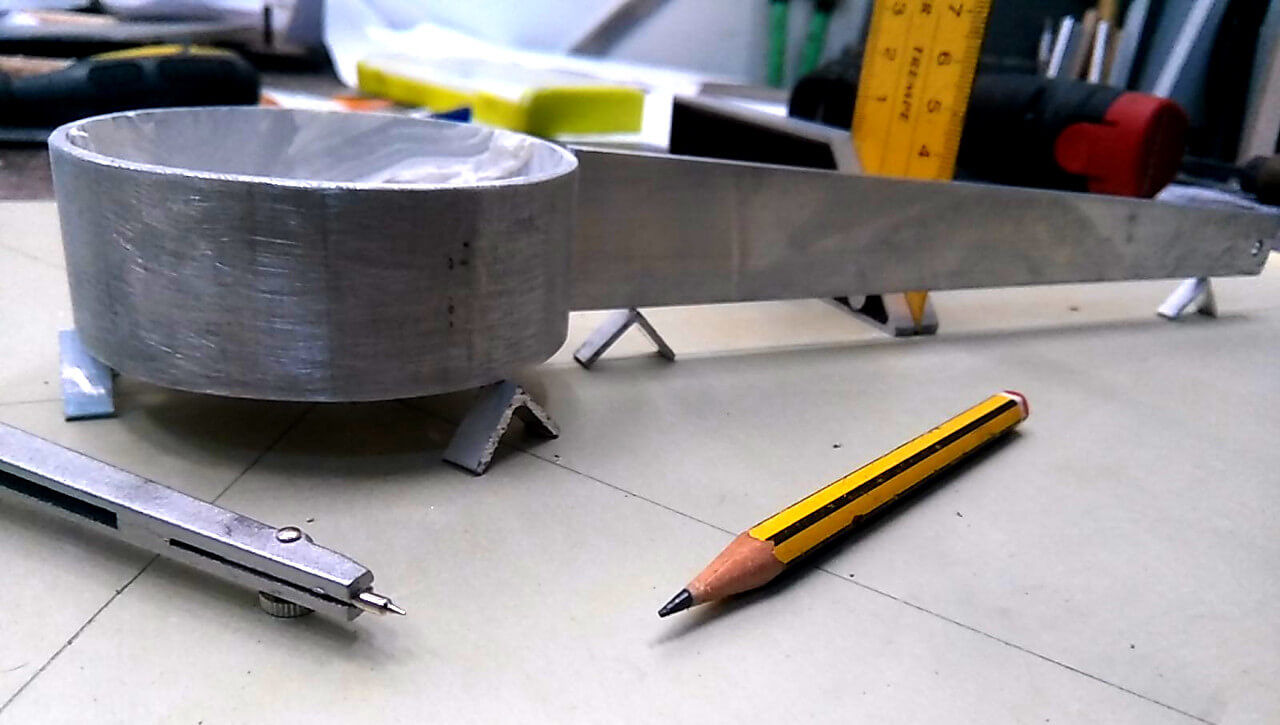

High quality plywood and aluminium will confer an exceptional rigidity to the telescope. We want the mirrors alignment to be kept when moving the telescope from zenith to horizon. Six strong cylindrical tube legs 30x27mm will hold up the secondary mirror and focuser minimizing the tipical loss of alignment when changing the altitude of the telescope.

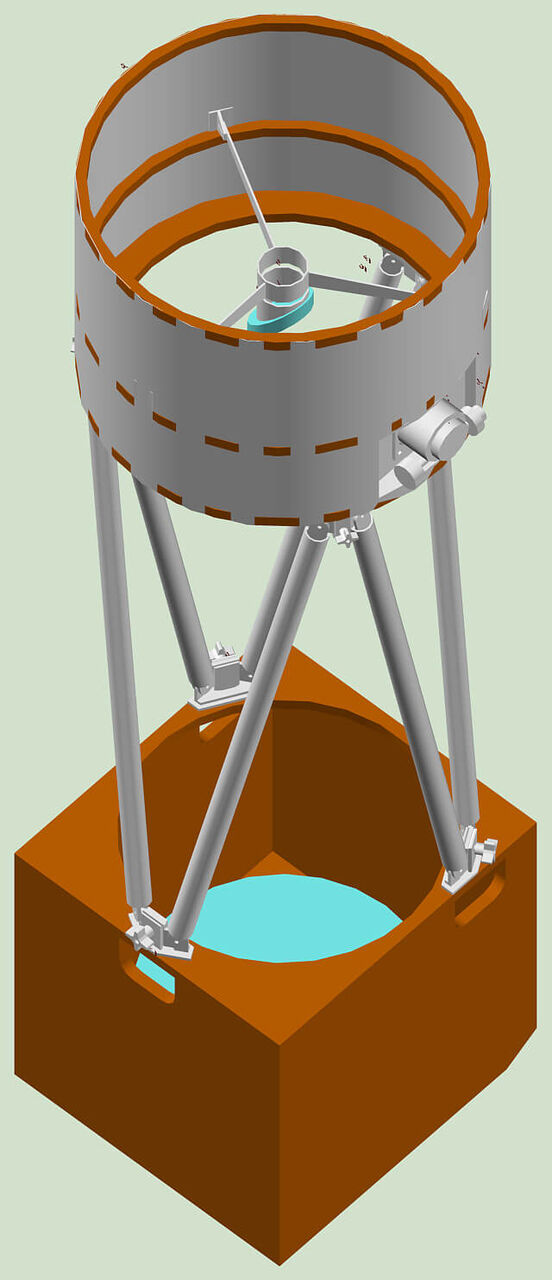

3.- Precision of optical alignment.

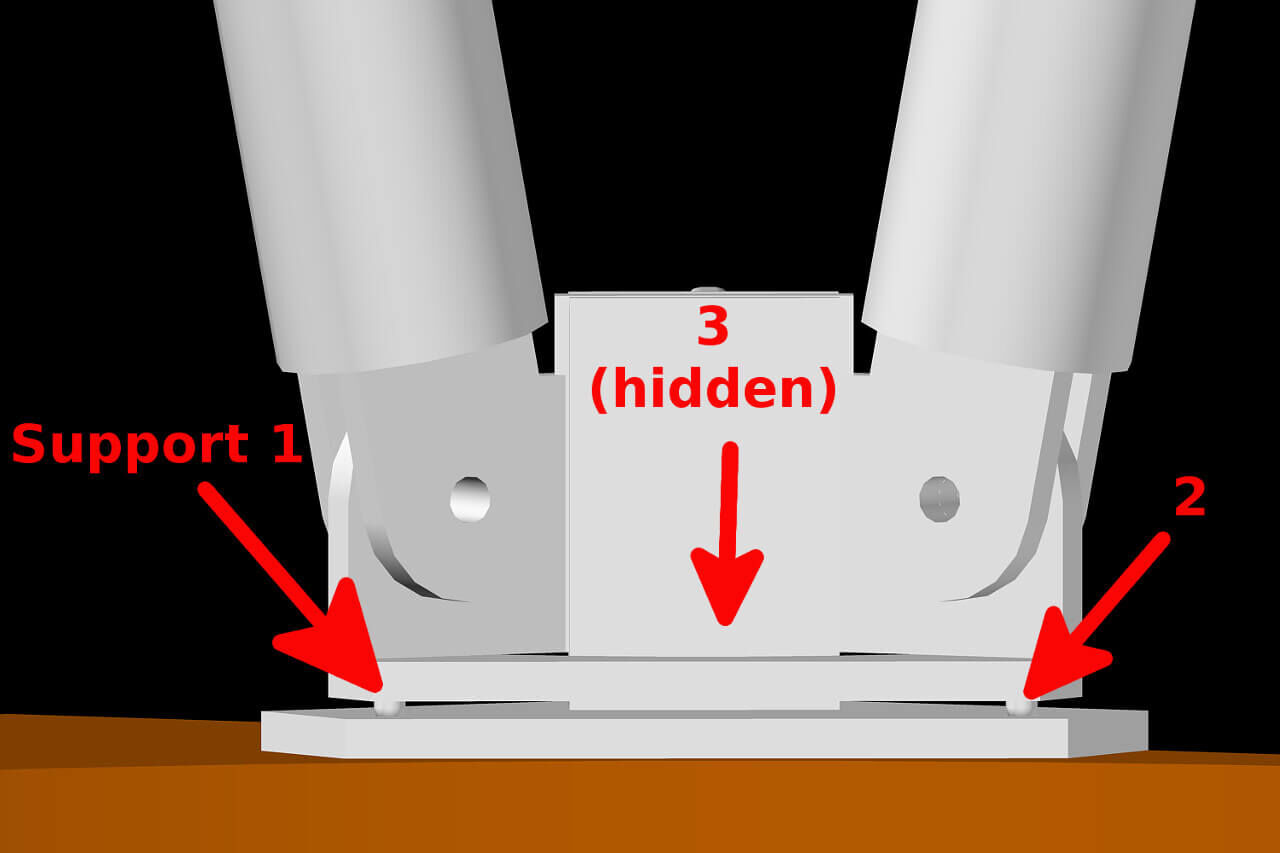

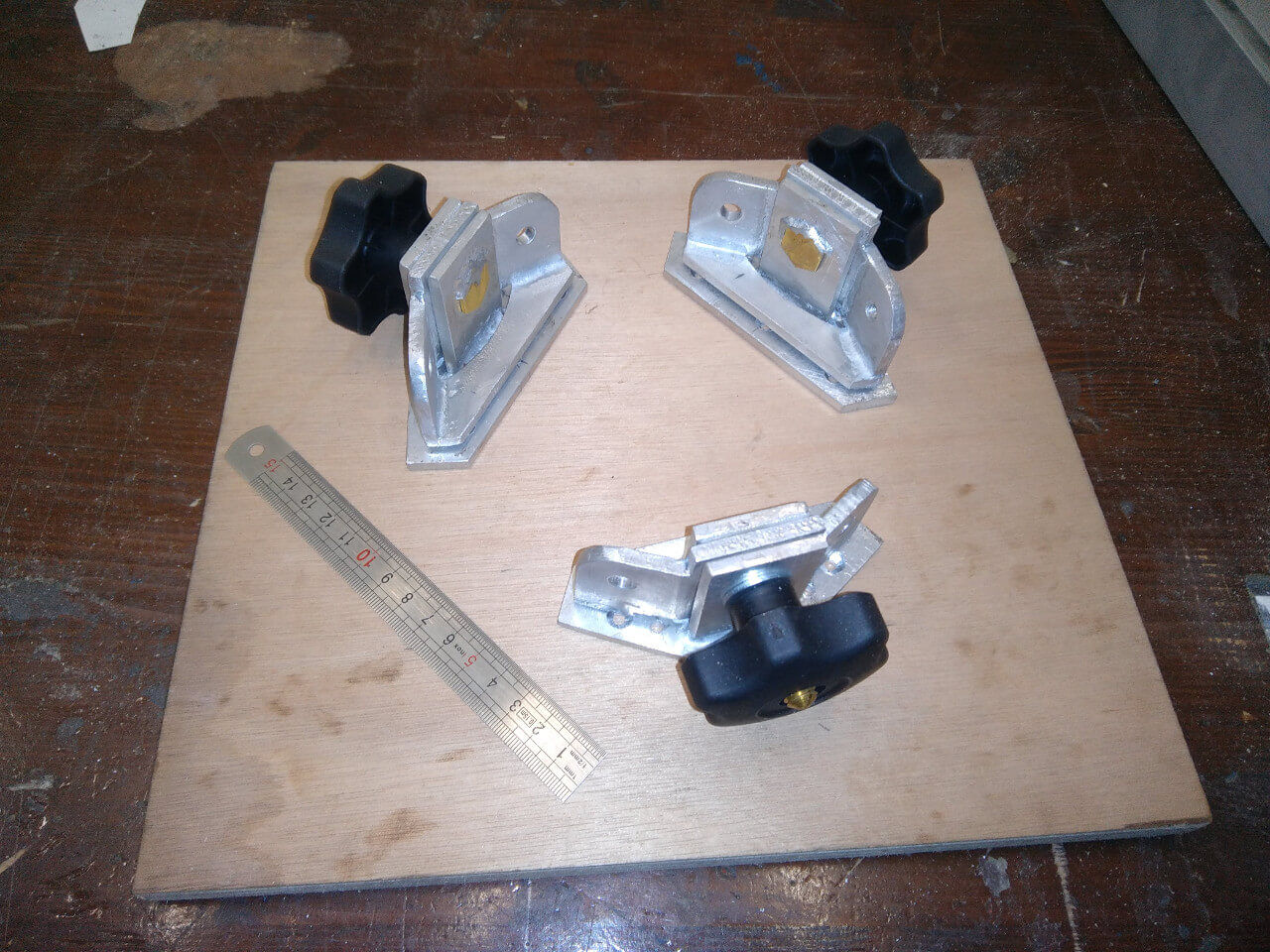

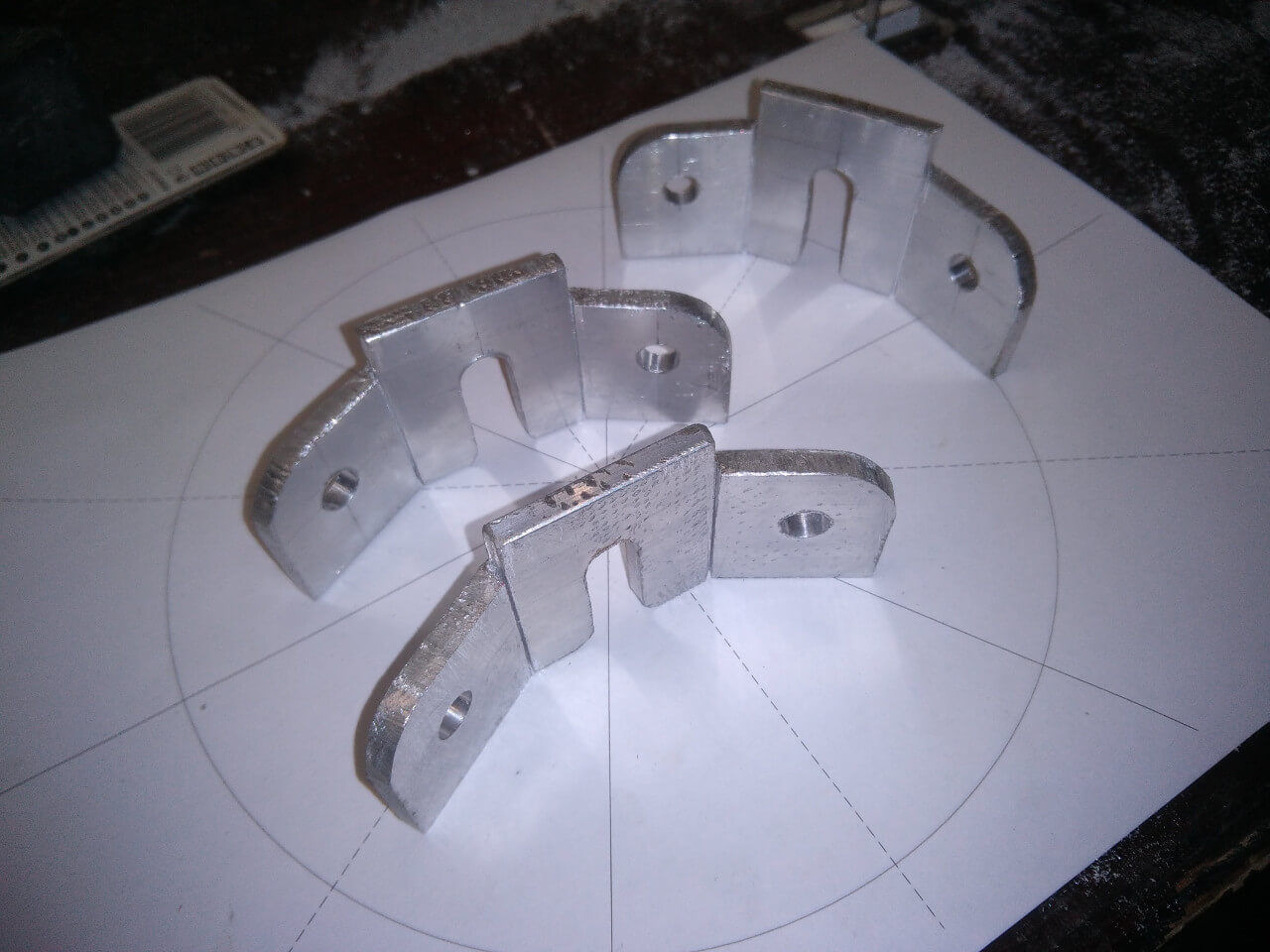

Isostatic positioners is the motto here. Each couple of legs from the upper part of the telescope containing the secondary mirror are joined to the rocker box by 3 brass supports. The plane containing the 3 supports forms a triangle with no possible movement when changing the direction of the telescope.

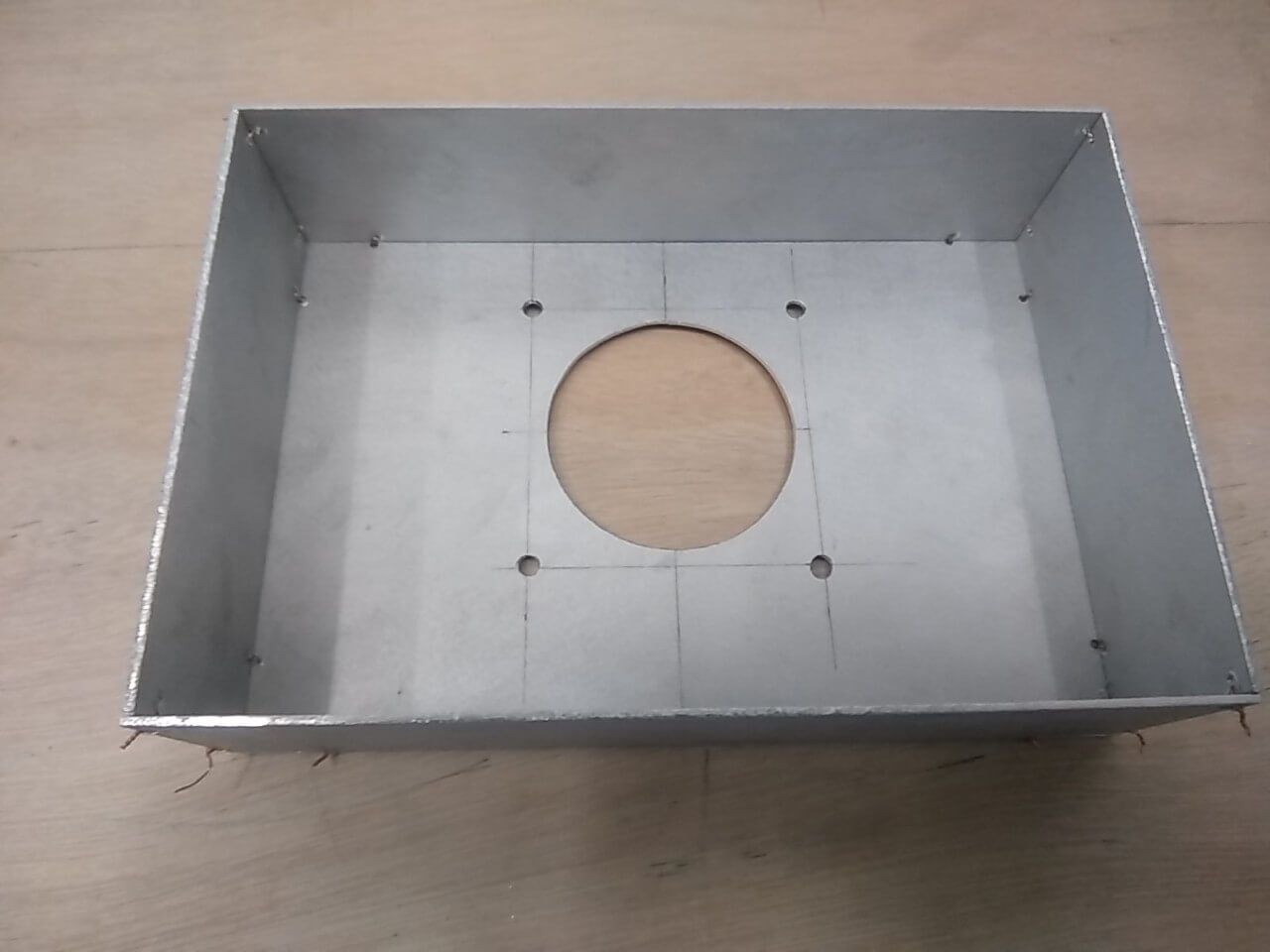

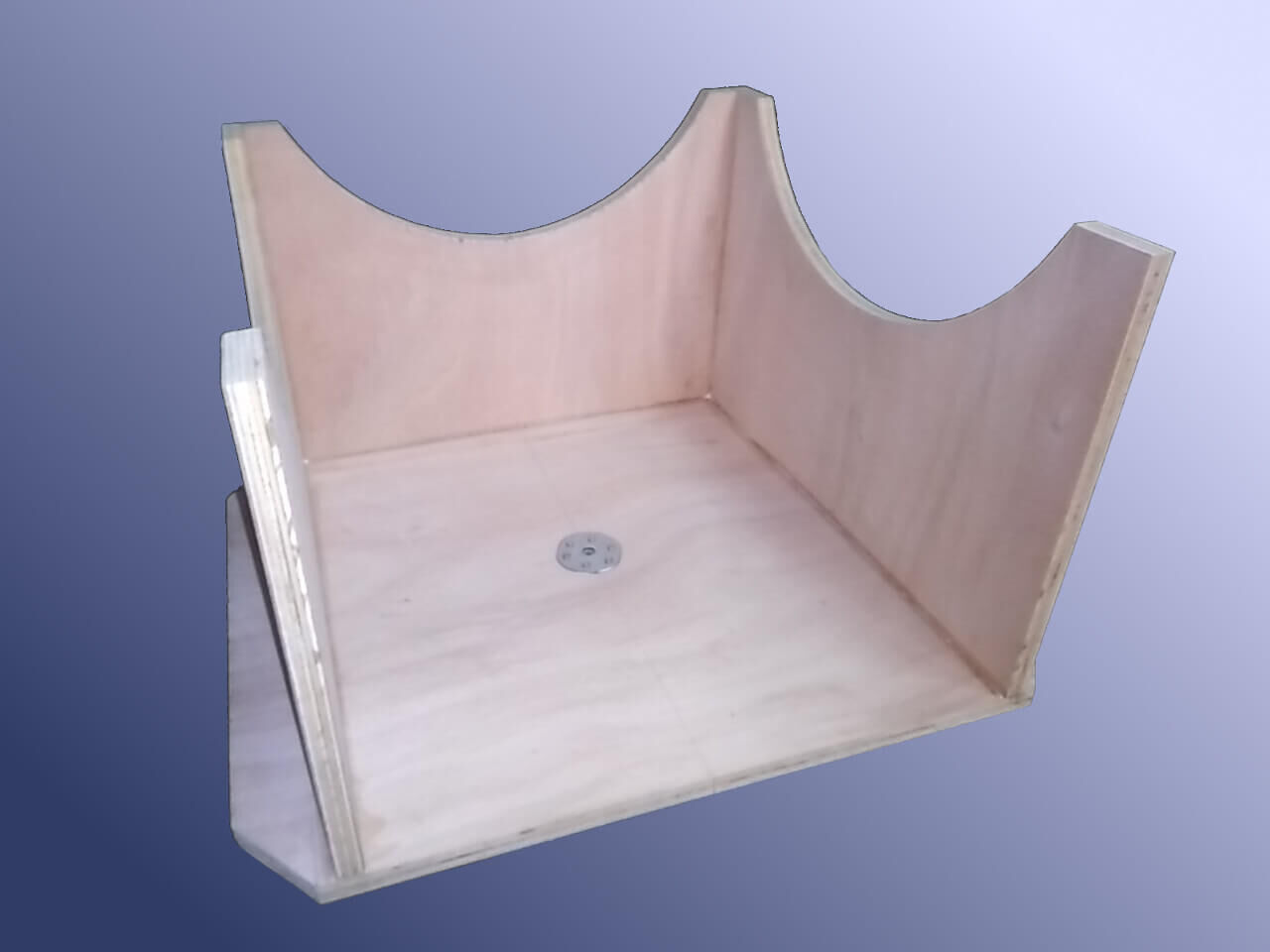

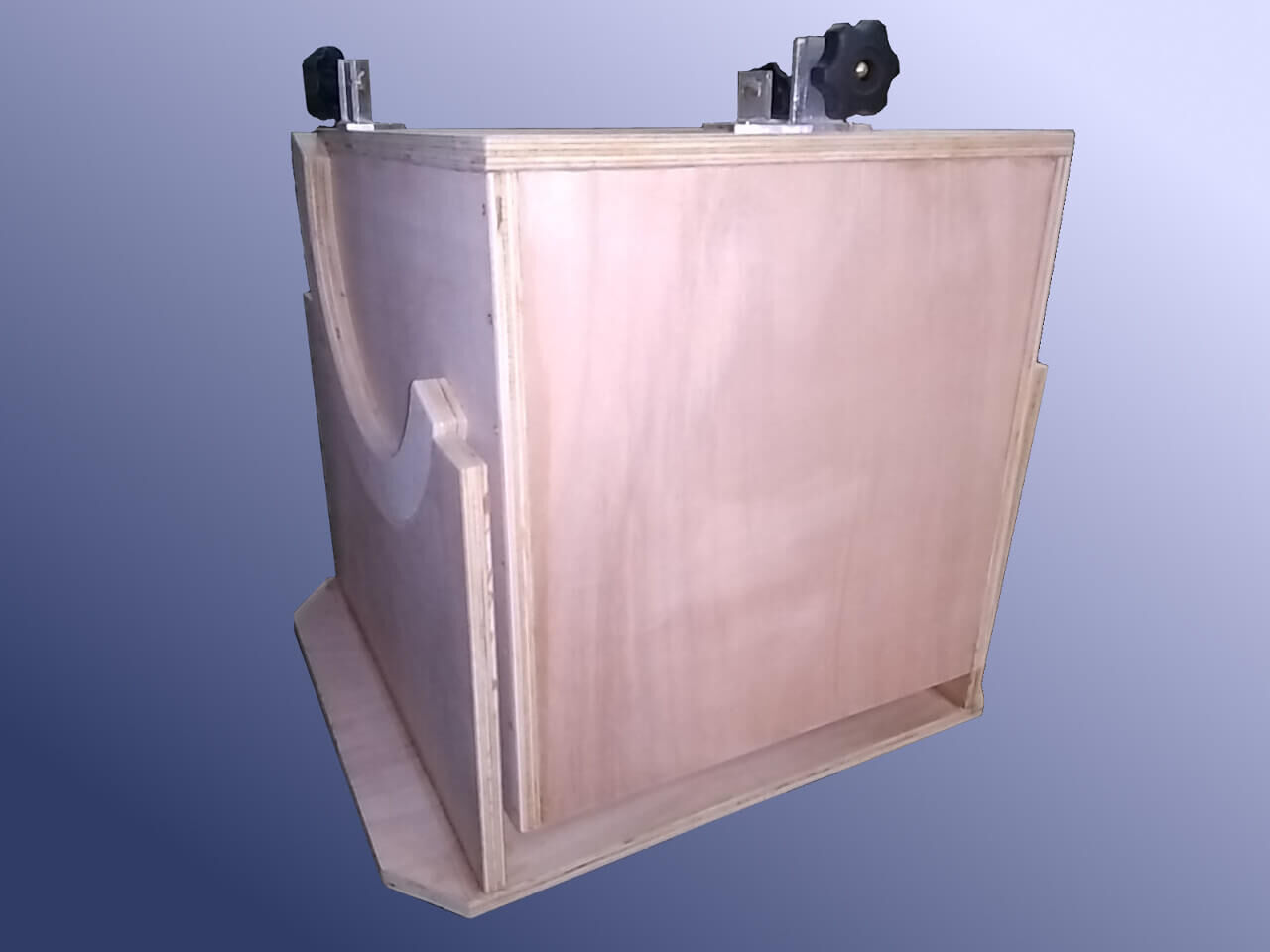

4.- Resistance of the rocker box to humidity.

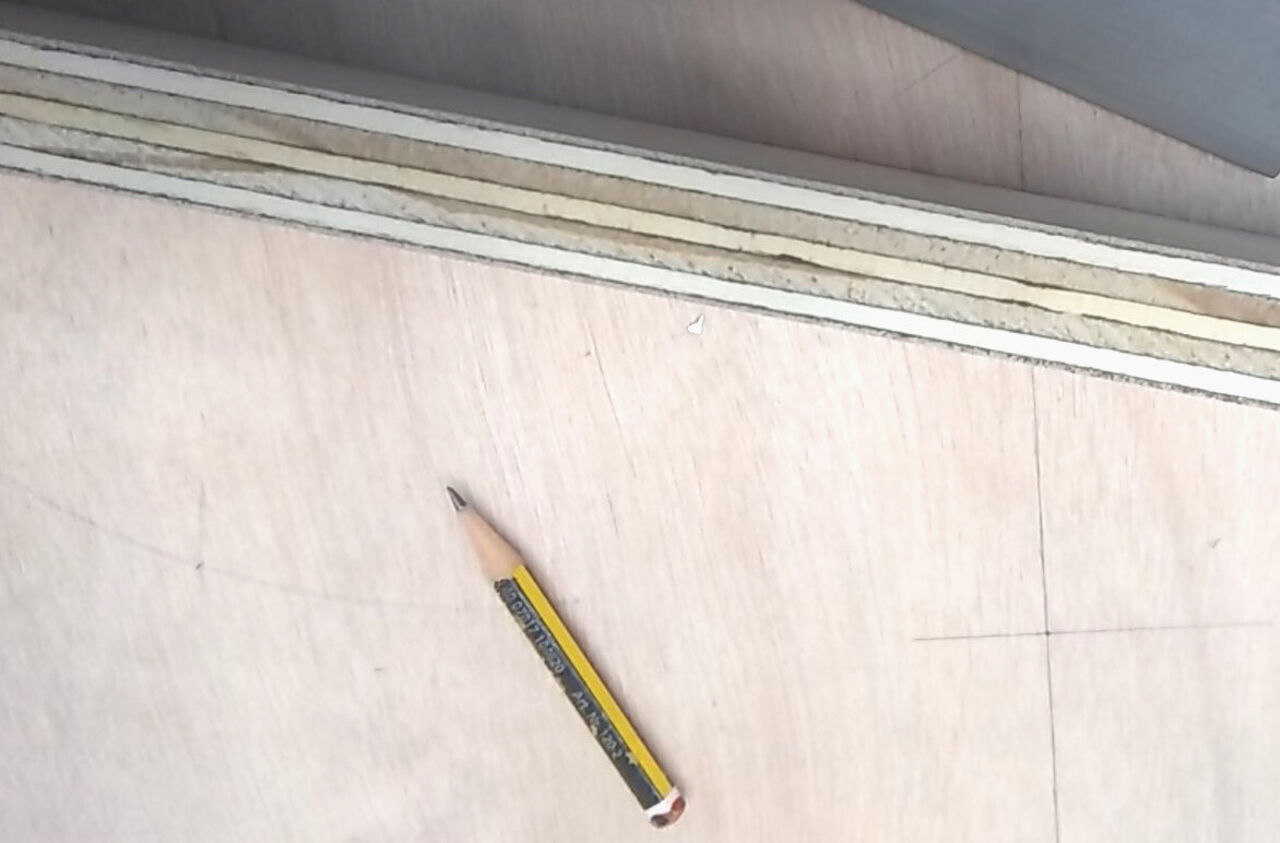

Unlike similar telescope from Skywatcher and Meade our telescope bottom box will be made of water resistant plywood (unlike particle bloard being used by Skywatcher and Meade).

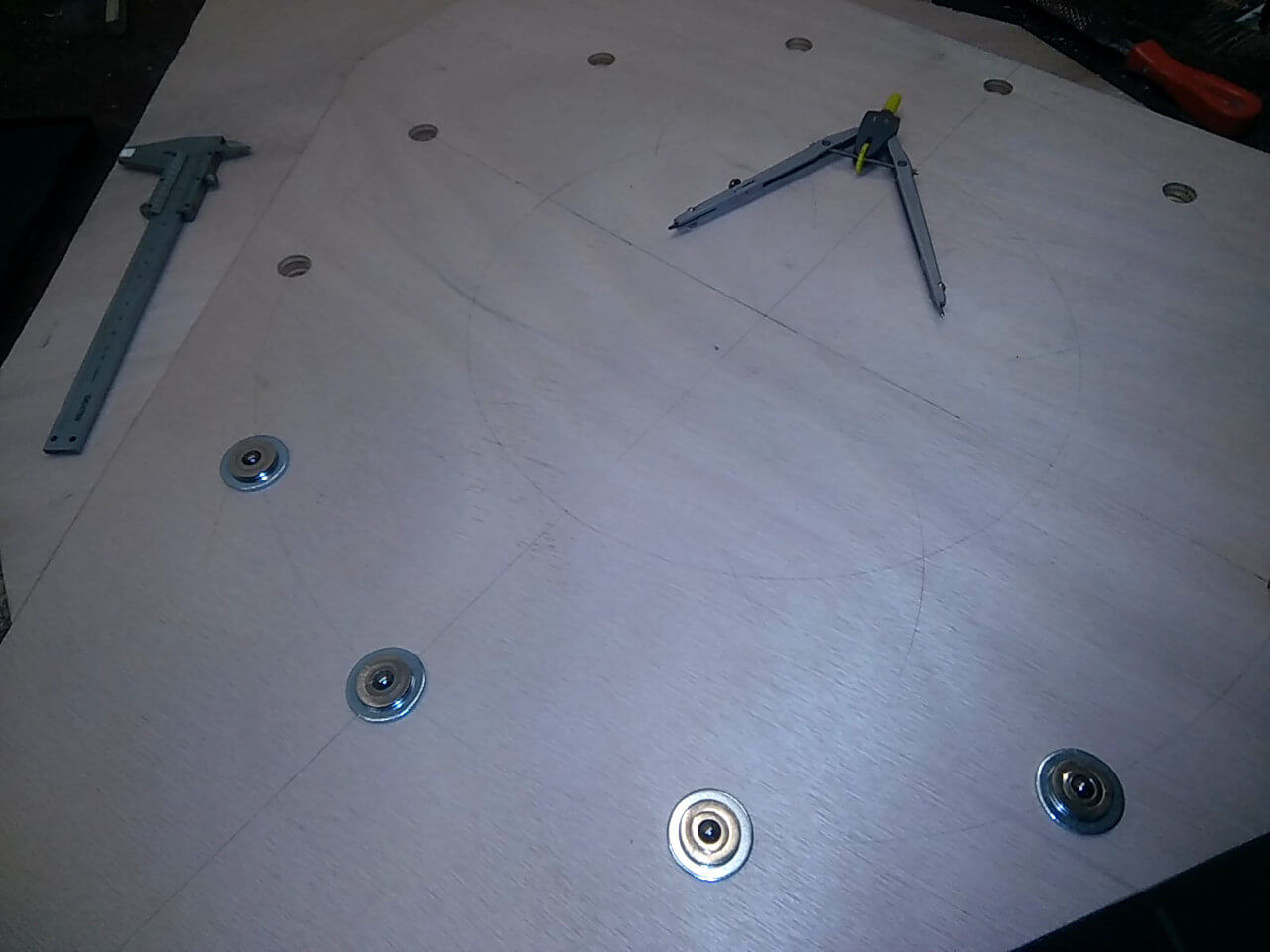

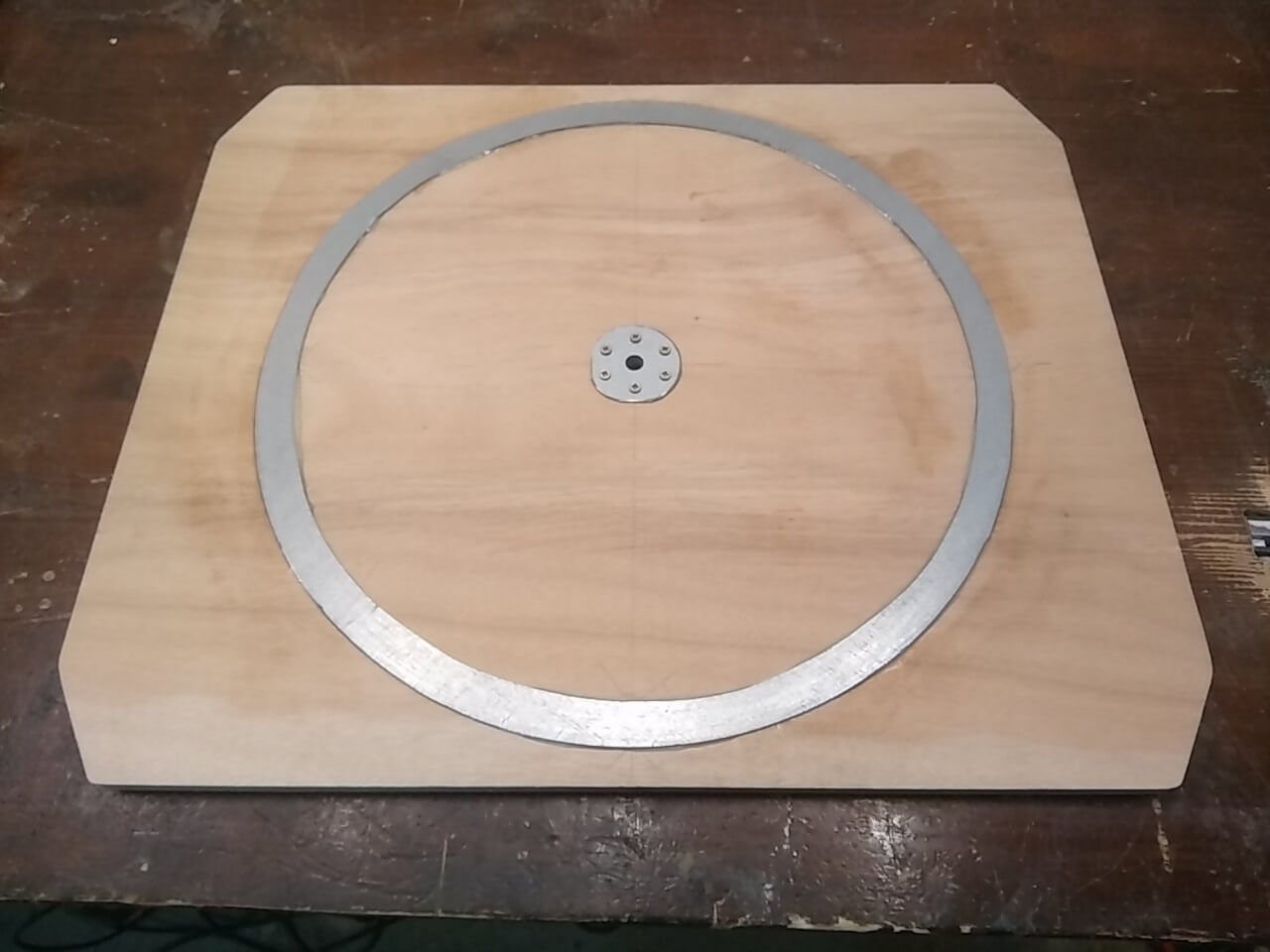

5.- Softness and precision pointing the telescope.

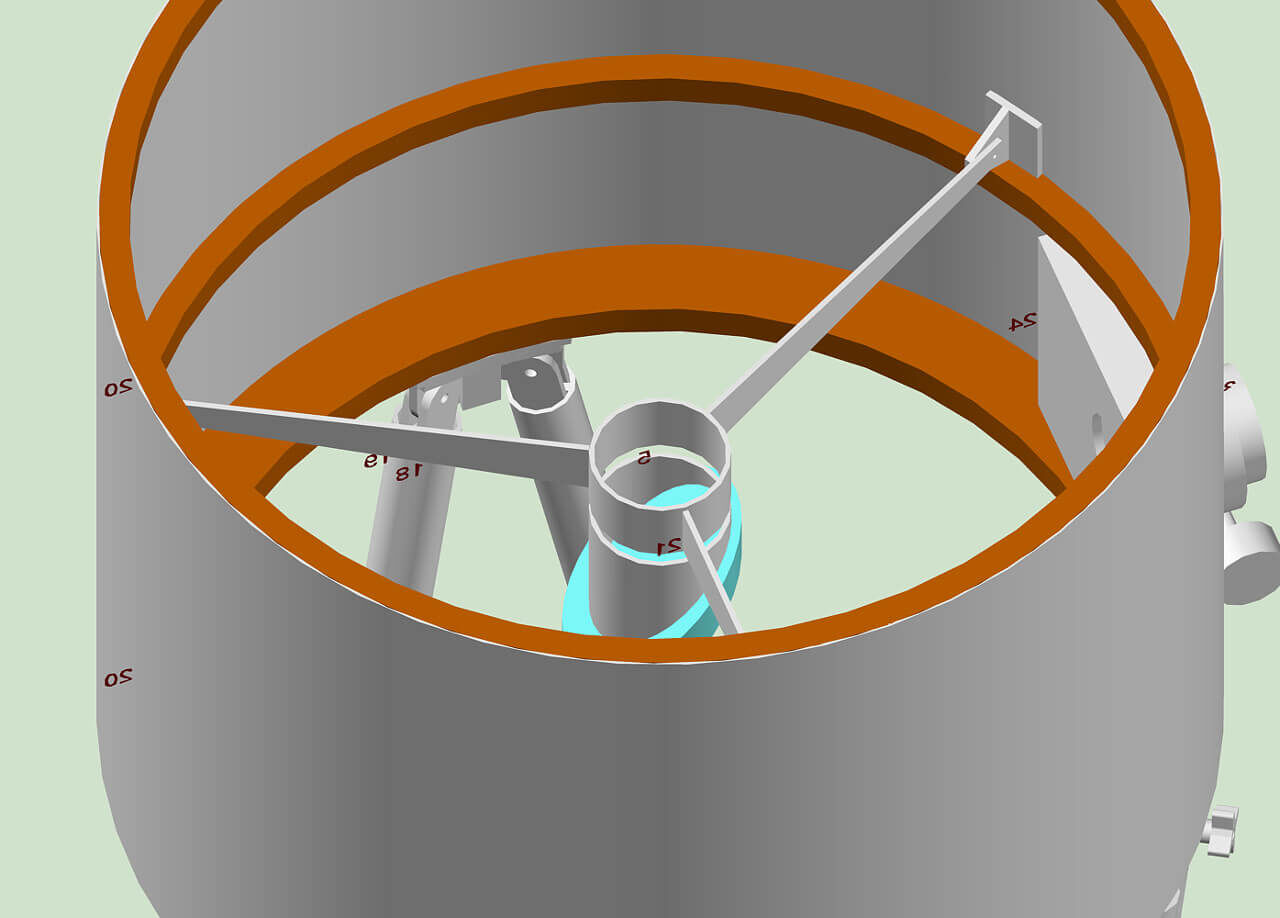

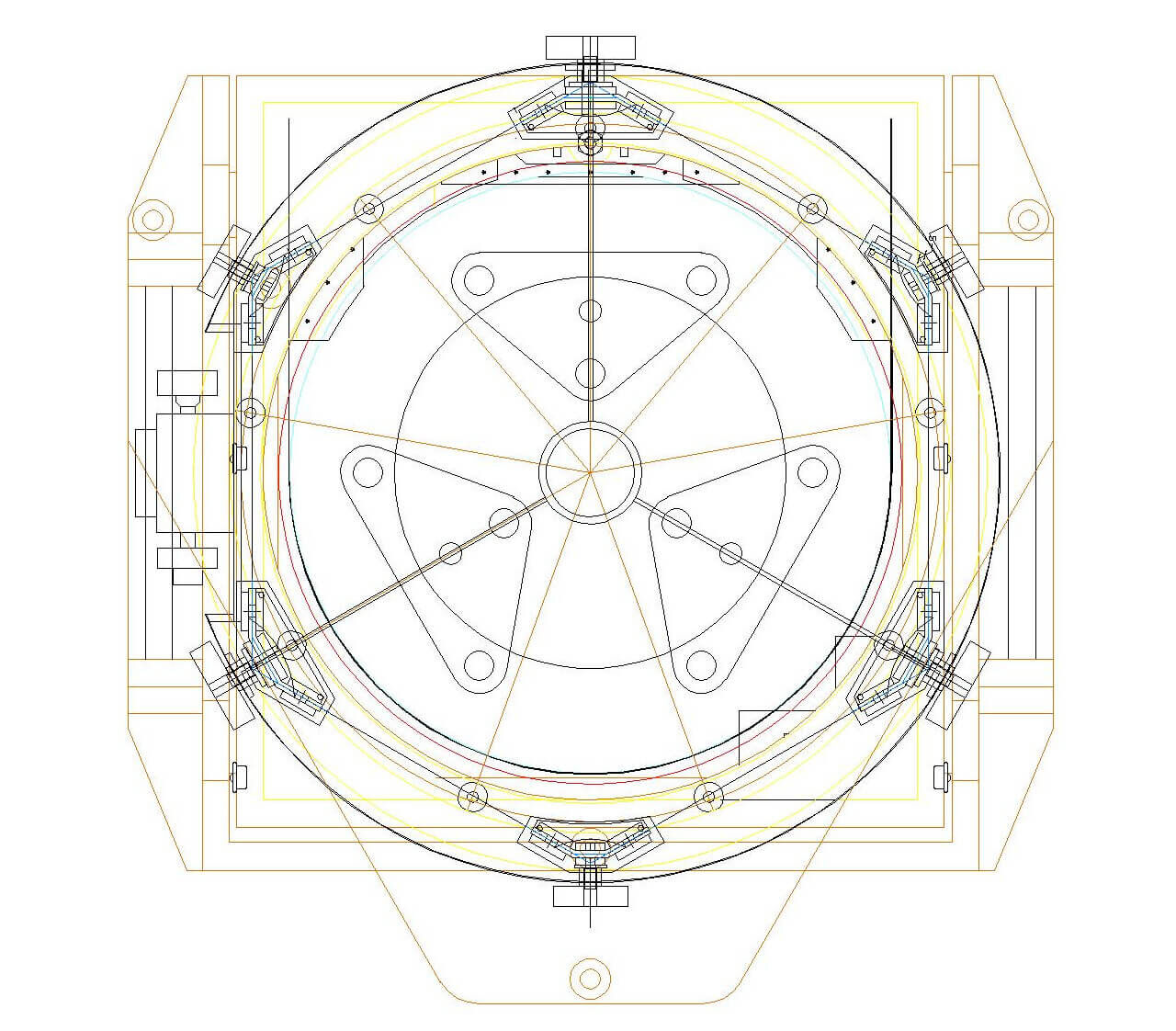

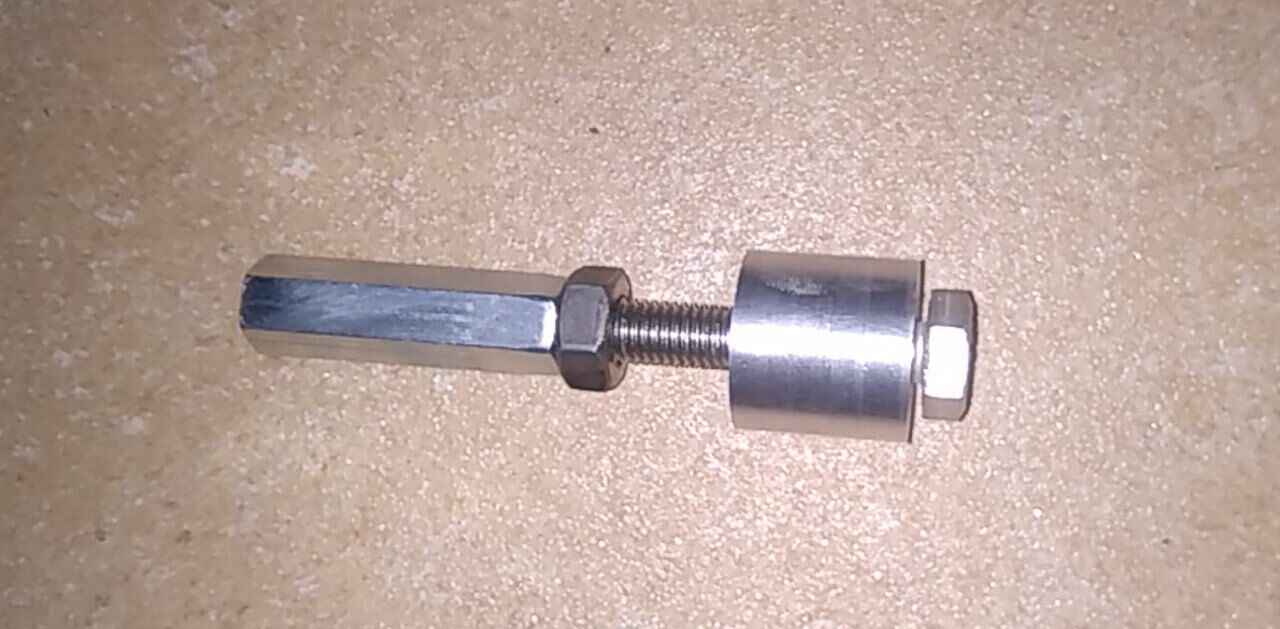

The vertical axis of rotation of dobsonian telescopes often produces unwanted movements and jerky rotation. Our telescope will solve this rotation with a innovative solution. Nine roller ball bearing units each one having a capacity of 15 kg will unsure a soft and precise rotation.

6.- Basic astrophotography ability.

Dobsonian telescopes are optimized for observation. For that the secondary mirror is as small as possible to reduce the shadow it projects on the main mirror. But this has a drawback as the focal plane is too close to the upper cylinder englobing the light path. If we want the camera ship to coincide with the focal plane, the camera will be on the path of the light and will produce shadow on the main mirror. On newtonian telescopes for astrophotography, the secondary mirror is slightly bigger and closer to the main mirror. In the case of the telescope being built at astroGC, we want both a small secondary mirror and photography ability. For that, the legs supporting the secondary mirror will be adjustable in length.

7.- Optical quality.

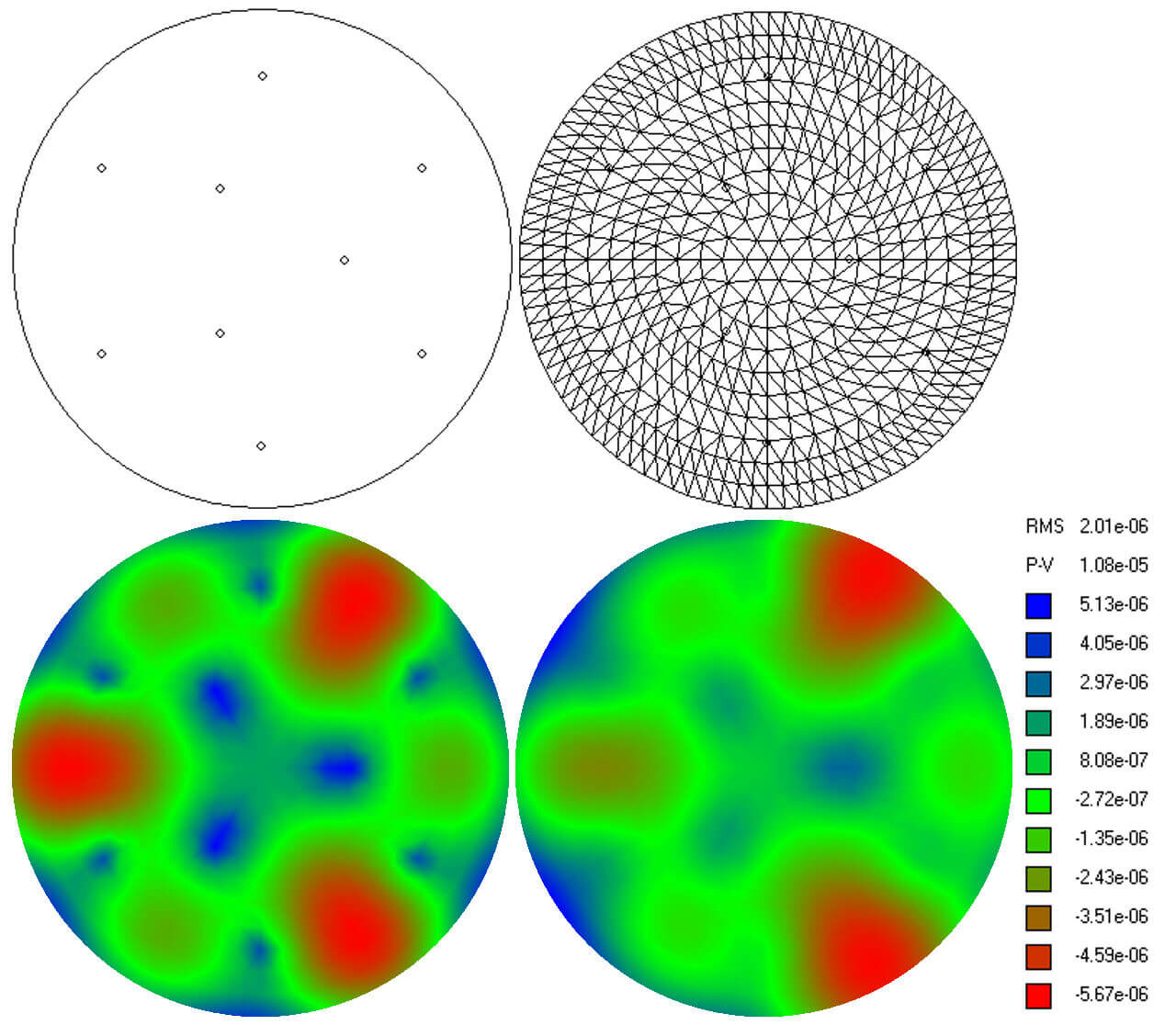

We have chosen a BK7 glass as substrate for the main mirror because of its high homogeneity. The surface of the parabolic mirror is diffraction limited. The reflectivity will be of 94% quartz overcoated. Its diameter will be of 405mm an focal lenght 1800mm (ratio f/4.5). The mirror thickness will be of 45.3mm.

8.- Moon light protection.

The upper cylinder protecting the secondary mirror from any disturbing light source (like the moon) will be about 50% bigger that usual telescopes from Meade and Skywatcher.

9.- No flares images.

Four legs supports of secondary mirrors produce disturbing flares around the stars.

We will be using 3 legs supports at 120º and this will remove flares.

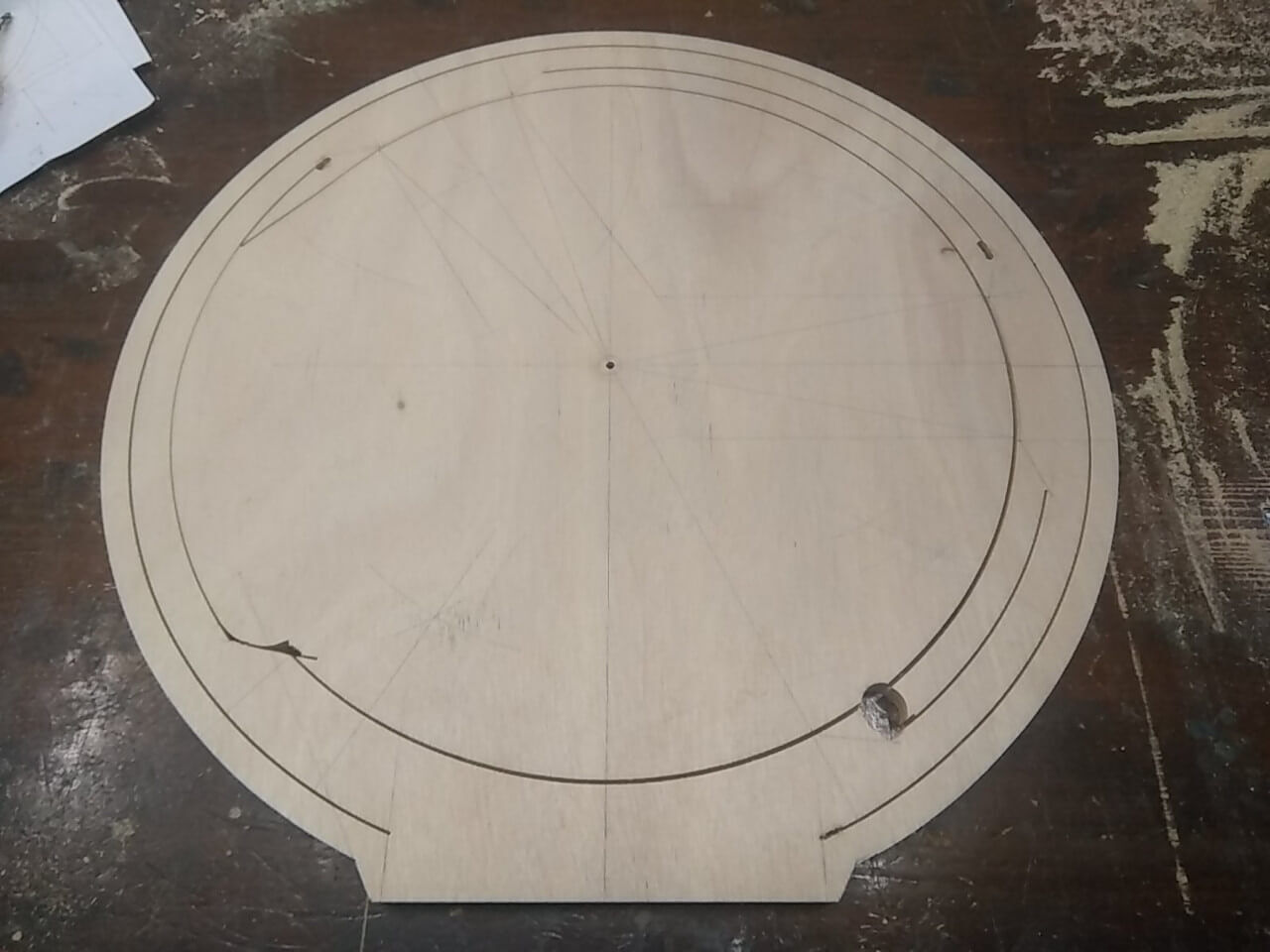

10.- Mirror cell optimization.

The mirror cell has been calculated using the computer program PLOP. A 9 points support has been selected, with a steel sling for better behaviour at low altitude. The results from PLOP show excellent RMS and P-V error.